Absolute Length Measurement

Overview

The Metsen ALM is a non-contact measuring solution for emerging length or width of continuous-cast product. The ALM provides real-time emerging length with accuracy up to 3mm without the need for installing equipment in hazardous locations.

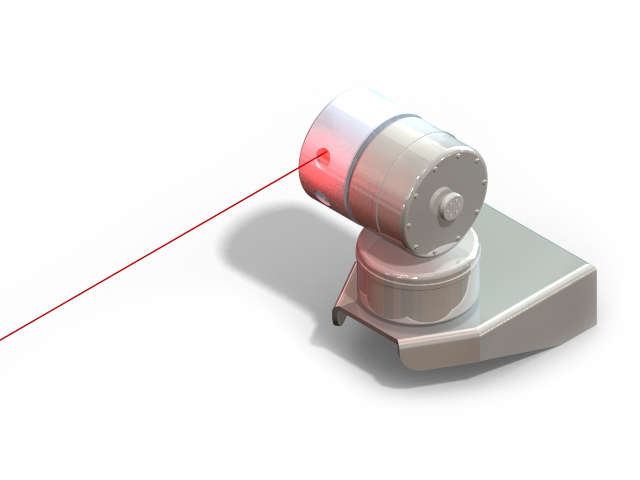

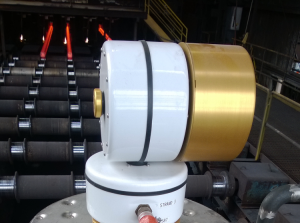

The ALM utilizes a gas-cooled high-accuracy pan-tilt gimbal and a low-power class-2 distance laser to track product as it is being cast. The unique hardware and software of the ALM allow the devices to be installed well up and away from the run-out bed, ensuring easy maintenance and increased system reliability.

How it works

During casting the ALM devices track the face of the emerging product using the pan-tilt gimbal to keep the laser squarely on the billet, bloom, slab, or round.

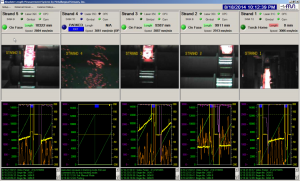

The ALM software handles the calculations necessary to provide highly accurate emerging cast length and casting speed.

When the torch clamps engage, the ALM then tracks the torch carriage, providing a final cast length for each product.

After the cut has completed the ALM tracks the torch back to its home position and accounts for any variability in the next set of measurements.

Features

Metsen ALM devices can be mounted in any position or orientation where they have a clear view of the face of the cast product and the torch carriage. The installation requires no precise alignment.

The Metsen ALM control software runs on any Windows platform and handles up to 6 casting strands.

Data and video for each cast product are individually archived for later review.

The Metsen ALM software uses OPC-based integration into any Level 2 system.